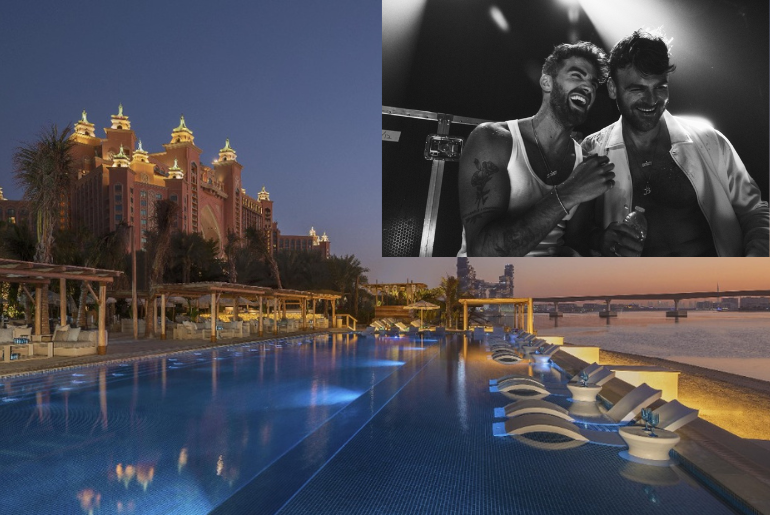

GRAMMY® Award-winning, RIAA platinum-certified international icon Tiësto has joined forces with multi-platinum singer/songwriter Tate McRae and Dubai’s ultra-luxury resort Atlantis The Royal to create the spectacular new single, “10:35,”.

The visual is highlighted by a performance from Tiësto and Tate throughout the stunning Atlantis the Royal resort, with the Dubai skyline as the glittering backdrop.

Also read: Mind Blowing First-look Of Jenga-style Dubai’s Atlantis The Royal Hotel Unveiled

“10:35” – An Ode To Atlantis The Royal

10:35 is inspired by and encapsulates the essence, energy and electricity of Atlantis The Royal, the newest icon of the Dubai skyline and the world’s most luxurious resort. When first introduced to the resort’s architectural plans, Tiësto honed in on the duality of the daytime experience of luxury vs the nighttime’s spirit of possibility and excitement. This juxtaposition fueled the idea for the time where day turns to night and that experience shifts – hence, “10:35.” McRae, who spent time growing up in the Middle East, proved a perfect partner, her vocals providing the ideal complement to the aspirational Atlantis The Royal brand.

“I’m happy to announce I’m doing a partnership with the Atlantis The Royal property in Dubai with Tiësto,” said Tate McRae. “It’s always exciting to branch out and work with different brands and artists. The music video is unlike anything I’ve seen before, and the hotel is just unreal.”

“We are beyond excited that Tiësto, a music icon, and Tate McRae – one of today’s hottest stars, have joined forces to create this incredible track to celebrate Atlantis The Royal,” says Tim Kelly, Managing Director of Atlantis Dubai. “10:35’ completely captures the vibe and energy of the hotel and expresses the unmatched daytime and night-time experience we have to offer. Shooting the music video at the resort is a show-stopping way for us to tease our guests and demonstrate the unrivalled luxury Atlantis The Royal promises ahead of the Grand Reveal in January. This is it.”

Also read: You Could Soon Book A Room In This Moon-Shaped Resort Being Built In The UAE

About Atlantis The Royal

Crafted by the world’s leading designers, architects and artists, Atlantis The Royal is a destination where everything has been designed to challenge the boundaries of imagination. With artful masterpieces, iconic entertainment, beautiful craftsmanship at every turn, premier dining, and the highest level of service.

To be one of the first guests to stay at Atlantis The Royal, reservations are now open with stays from 2023 onwards. To book, please click here

3 Comments

Personalized embroidered badges

September 4, 2024I found this very helpful and will be sharing it with my friends.

https://owlbadges.com/

Mancubus0Vonia

September 29, 2024Are you interested in increasing the reliability and efficiency of your equipment? Introducing the Balanset-1A – an innovative balancing and vibration analysis device that has proven its effectiveness in practice.

The Balanset-1A includes two vibration sensors and a laser tachometer, facilitating balancing in one or two planes. This device measures vibrations and automatically calculates balancing parameters, streamlining the process.

Users commend the Balanset-1A for its high accuracy and ease of use. The device archives all results, facilitating easy report creation and repeated balancing procedures, which saves time and resources.

Don’t overlook the chance to increase your equipment’s efficiency. Order the Balanset-1A today and enjoy its benefits firsthand.

Here you can read more about [url=https://vibromera.eu/] Vibration diagnostics and control methods for maintenance [/url]

Mancubus0Vonia

October 3, 2024horizontal balancing machines

Understanding Horizontal Balancing Machines

Horizontal balancing machines are essential technological devices used for eliminating static and dynamic imbalance in various rotors. They are particularly significant in industries such as automotive, aerospace, and manufacturing, where precision in the rotation of machinery is crucial. In this guide, we will explore the types of horizontal balancing machines, their design features, and how you can build or choose the right one for your needs.

Types of Horizontal Balancing Machines

The primary distinction between horizontal balancing machines lies in their support structures, which can be classified into two main types: Soft Bearing Machines and Hard Bearing Machines. Each design serves specific operational needs and possesses unique attributes that influence their performance in balancing rotors.

Soft Bearing Machines

Soft Bearing Machines utilize flexible supports based on spring suspensions or other compliant materials. The natural frequency of these supports is designed to be at least 2-3 times lower than the rotor’s operational speed, allowing for effective balancing across various rotational frequencies. These machines are particularly popular among local manufacturers for their relative simplicity and manufacturability.

For example, a Soft Bearing machine might use a suspension system that allows the rotor to experience minimal resistance during operation, thereby enabling accurate measurement of vibrations or forces that help determine corrective weight placements. Such machines are favored for applications including balancing turbochargers, drive shafts, and various specialized machinery used in multiple industries.

Hard Bearing Machines

In contrast, Hard Bearing Machines feature rigid supports that are designed with intricate slots or cut-outs. They provide a more robust structural integrity compared to their soft counterparts. The natural frequencies of these supports significantly exceed the maximum rotational speeds of the balanced rotors, making them suitable for high-precision balancing across a broad range of rotor mass and dimensional characteristics.

These machines excel in scenarios where balancing needs to occur at relatively low rotational speeds, providing versatility for balancing various rotors such as those found in automotive and industrial applications. Hard Bearing Machines are also known for their ability to deliver more consistent results in diminishing the rotor’s residual imbalance.

Key Components of Horizontal Balancing Machines

Regardless of the type, every horizontal balancing machine shares some fundamental components:

Support Structure: This is where the rotor is mounted and rotated. Designs vary depending on whether the machine is a Soft Bearing or Hard Bearing type.

Drive System: This includes motors and belts that rotate the rotor, providing the necessary operational speed for balancing.

Measuring Systems: Sensors are crucial for detecting vibrations and calculating imbalance. They analyze data to help position corrective weights accurately.

Bedframe: The foundation that supports the entire machine and minimizes external disturbances during operation.

Requirements for Constructing Horizontal Balancing Machines

Building or configuring a horizontal balancing machine involves several design and operational requirements. These include:

Choice of Bearings: The selection of appropriate bearings is crucial, as they support the rotor and influence the machine’s vibration characteristics.

Construction of Bearing Units: Proper alignment and configuration of bearing units ensure the accuracy of measurements and the machine’s ability to function under various service conditions.

Accuracy of Measurement Systems: The measuring systems must be able to capture and process vibrations accurately to ensure effective balancing.

Operational Stability: The overall design must minimize vibrations and disturbances from external sources to maintain measurement integrity.

DIY Horizontal Balancing Machines

Many individuals and organizations seek to create their own horizontal balancing machines to meet specific operational needs or reduce costs. Building such machines requires careful planning and adherence to established design principles; however, it can lead to significant savings. Insights into common configurations and operational principles can guide those looking to embark on this project.

DIY builders should consider resources available through various platforms, including information provided by experts in the industry. They offer recommendations on structural designs, material choices, and effective measurement systems that can simplify the construction process and enhance the operational capabilities of home-built machines.

Performance Validation and Testing

To ensure accuracy and performance, horizontal balancing machines should undergo a series of validations, including geometric accuracy checks, dynamic characteristics assessments, and operational capacity evaluations. Ensuring compliance with established industrial guidelines and standards allows for the effective use of these machines across various applications.

For those building horizontal balancing machines, regular testing and validation of the machine’s capabilities are essential. This includes assessing the balancing quality achieved and making any necessary adjustments to improve performance over time. It involves recalibrating measuring systems, validating the placement of corrective weights, and ensuring the machine operates within the desired operational frequency parameters.

Conclusion

Horizontal balancing machines play a crucial role in ensuring that various machinery operates efficiently and without undue vibration. Understanding the types, design features, and key components enables manufacturers and DIY builders to effectively select or create balancing machines tailored to their specific needs. As industries continue to evolve, the importance of precision in balancing machinery will remain a vital consideration for ensuring operational success.